What you are about to read is a foundational document created by me, Noah Hickman, the Longhorn Racing Solar Fergo System Lead for the 2024-2025 competition season. I have chosen to create this document to make a referenceable database for any new and future ergonomics subsystem members. Though I made this documentation purely off my knowledge and research of solar car ergonomics construction, this is a universal document that includes useful information for ergonomics design in general, which means any and every team, LHR Combustion, Electric, Solar, or even teams beyond UT Austin can hopefully utilize this document. I hope for this document to aid in the design, procurement, and manufacture of any and every piece of a competition car's ergonomics design.

This document or rather my experiences and knowledge gained from my time in LHR is not accurately portrayed or represented without acknowledging those who helped me along the way. From Solar’s team captain, to chief engineer and mechanical lead, as well as members and leads of both the Combustion and Electric team, I cannot thank those enough for the impact they have had on my development as an engineer, and therefore the creation of this document and information therein.

Goals of the Ergonomics Subsystem (subject to change):

- Consider all and every component that the driver touches and uses during normal driving operations:

- This includes and is not limited to:

- Driver model

- Pedal box

- Driver Communications system

- Driver harness/seatbelt configuration

- Belly pan

- Driver seat

- Driver cooling

- Steering wheel

- Brakes (brake lines, proportioning valve, etc.)

- Parking/Handbrake

- This includes and is not limited to:

- Additionally consider items that shield the driver and that are specific to each driver (I say this as ASC requires multiple drivers)

- This includes and is not limited to:

- Ballast Box

- Frame cushioning/padding

- Driver shielding

- This includes and is not limited to:

- Take in any design considerations or concerns from systems such as Controls (Dashboard), Electromechanical (Cooling), and Dynamics (Brakes, Steering Wheel) to ensure smooth integration and that all design cases are met

- To meet ASC guidelines (which directly affect the ballast box, steering wheel, braking system, seatbelt setup, etc.), design each component to meet standards

- Utilize topology optimization and prototyping to refine each design, maximizing the weight to stiffness ratio, and upholding high DFM (design for manufacturing) standards

- Perform FEA simulation via SolidWorks or ANSYS (preferably ANSYS) in order to once validate FOS of at least 1.1+ and ensure parts are optimal for their average use/load cases

- Manufacture each necessary part via manual milling, lathing, CNC, TIG/MIG welding, etc. etc.

- Integrate with the frame and other systems

TLDR: One big subsystem, many smaller (but highly significant) projects

Disclaimer before we start: I have been previously a Frame member and Frame lead, with no role or real experience pertaining to Ergonomics. With that being said, I have a base level knowledge from my own research and prior intuition into car design as a whole. Please do not take anything I say as the absolute final word, this is merely meant to try and guide you in the right direction and give you a jumping point to go off of. Throughout the guide, I will do my best to cover everything as it pertains directly to Ergonomics but again, don't just go off of what I say. Be skeptical, do your own research, and create your own knowledge base and decisions.

Foundational Documentation/Good Reads (in a good reading order):

- /wiki/spaces/LHRSOLAR/pages/131107528 → This is a non-negotiable must read for all members, as it specifically lays out the guidelines and regulations we must follow to ensure we meet ASC and FSGP standards.

- Ergonomics Lead Summary by Rachel Dong → Though this summarizes the lead role, this is a defacto exit summary from a previous Combustion lead and guide on what the Ergo subsystem does, what to consider, what sort of deadlines you'll have, and primary concerns for the subsystem.

- Cockpit Design of a Formula Student Race Car: An Ergonomics Study → Though based on FSAE, this provides a good overview onto the design methodology of the cockpit of a car, regarding what considerations to take in, what you are designing for, and how those can be affected by the design.

- TIG Welding Topics - Miller Welds → (Unlike Frame, there can/will be significantly less or no welding required for Ergo but it's possible) Just trust me on this one, welding is fun and fairly simple to learn, but not so simple to master and get good at. Use the resources available here and any mentors around, you WILL need it.

- The entire “To Win” series by Carroll Smith is a great series written on motorsport racing and race car development as a whole. These are great reads as a whole if you like cars, motorsport, and automotive engineering in general.

Necessary Fundamental Knowledge

To be successful with your many ergonomics projects, one must be knowledgeable in the realms of many foundational engineering principles, being primarily Solids, Statics, Materials, and even Fluid Mechanics/Thermodynamics.

DISCLAIMER:I never completed any of these classes upon first drafting this work, but these are continuously updated as a I venture into the topics in class, on my own, and as I encounter them in LHRS as a whole. 👍

Statics

Start here → Statics Lecture.pdf

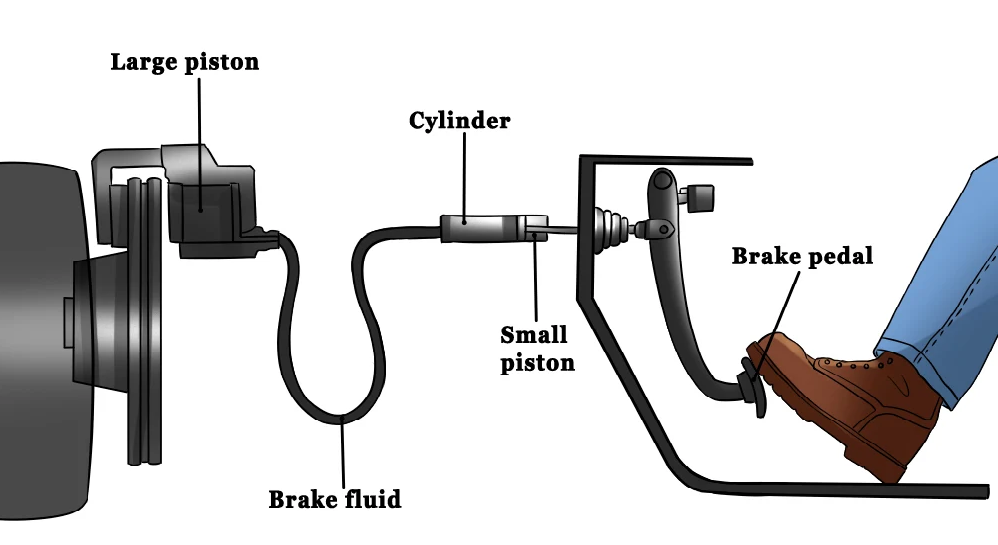

Pictured here is an explanation of moment as it pertains to the example of a brake pedal. The force at A causes a moment around B with the distances of 240mm and 100mm.

Moment

Firstly, many different static and dynamics ergonomics parts will experience various forces and moments when in use on the car.

For example, you have the driver putting force (causing a moment) on the brake and throttle pedals with his legs, while applying a grip force on the steering wheel, all while the equal and opposite contact forces from the seat and harness keep the driver at equilibrium and safe within the occupant cell.

- Force → load applied at a point, causes pressure and by extension stress (force over an area), displacement, work, etc.

- Moment → measure of a force times a perpendicular distance from a point (I.e. tendency of a force to rotate around an axis of an arbitrary point)

Takeaways from this → Each part takes on different loads and moments that we must tailor each design and mechanism for to take on

Inside each part, internal forces are present, which can cause different effects (i.e. compression → buckling, shear force → shearing, bending moment →bending stress, etc.)

- When designing a part, especially when FEA and additional analysis is required, one must consider the different types of forces acting on the part, and how each one can affect the overall part (i.e. where are the weakest points in the structure based on the loads placed on it?). Some parts may experience only one of these cases (think of a seat only experiencing shear forces caused by the gravity of the occupant), while some parts may experience multiple at the same time (think of a brake pedal with both compression and bending moment caused by the force of the driver's foot).

Axial Forces

- Axial forces (forces parallel to the center axis of the part) can cause compression or tension in a part, which can essentially be broken down into squeezing or stretching

- Too much of either tension or compression can lead to either plastic deformation or buckling

- Most parts are resistant to axial forces as compared to shear forces or bending moments (this can vary on the material, shape, and size of the part however)

- Buckling is more common in longer, less stiff parts (I.e. shorter, stiffer part → less chance of buckling)

Shear Forces

- Shear forces (forces perpendicular to the center axis of the part) can cause the shearing of a part

- Think of it as a cutting force, like scissors cutting paper, a force perpendicular to the part can sort of “cut” the part in half

Bending Moments

- Bending moments (forces that cause a rotation around a fixed point, causing bending) can cause bending stress (this is the root of most all problems in a lot of design)

- You can think of bending moments as the worst case scenario, not only are you getting normal stress loads, but you are getting transverse shear stress as well

- Bending moments have a lot to do with load pathing (i.e. if your load path is a straight line, no bending moment is caused (forces are only axial), but as soon as you introduce an angled path, bending moments are caused)

Torsional Forces

- Torsional (or twisting) forces occur when torque is applied about the longitudinal axis of a part

- A good way to visualize this would be when the driver continually tries to turn the steering wheel after they have reached the steering stops

- No more allowed rotation → torque is opposed → torsion (albeit not that much unless our driver is Bruce Banner or something) occurs

Supports will come in later when you take Statics/are introduced to FEA.

- Supports assume infinite stiffness in specific degrees of freedom. Some supports (like fixed) have reactionary forces and moments in all DOF, some like (roller and pinned) have reactionary forces and moments in only specific DOF

- All that matters is that different types of supports resist different types of forces/moments, which you can use to solve/isolate forces and understand the reactions happening in a system

- Supports are integral to setting up a simulation right. If you have too many constraints, your sim will be too stiff and you will have inaccurate results. Too little constraints, same problem, inaccurate results, that can cause you to falsely presume your part is safe/effective.

Friction is also present in some capacities within the Ergonomics system, with the main part being the braking system.

- Friction is the force that resists or opposes either

- a) relative motion → Kinetic Friction (although relative motion can be at rest so potentially Static Friction)

- b) impending motion → Static Friction

- Friction is made up of the coefficient of friction which is determined by the surfaces and materials you are working with and the normal force, the force pressing the contacting surfaces together.

- Friction is also most often associated with heat energy, meaning that when friction occurs, heat dissipation is likely to follow. Think of this as when you rub your hands together → friction occurs → heat follows shortly after

- As an example, friction is present in the braking system as when the driver pushes the brake pedal and shifts the braking fluid, which sends hydraulic pressure to the brake caliper, which cause the brake pads to contact the brake rotor, thereby causing friction, which then slows down the rotor and wheels, while also releasing some of the transferring kinetic energy as heat to the atmosphere.

Two Force Members

- A two force member in our case would be a tube with forces only acting in two locations, with the forces being equal opposite and colinear.

Materials

Start here → Materials Lecture.pdf

Every material is made up of a crystal structure (crystal defects, a unique organization of atoms, etc.) which leads to materials with unique/different properties (i.e. this is how you get alloys, a mixture of chemical elements with at least one metal)

- You can look more into this on your own, but essentially, we pick a tube material based on its makeup and its properties (weight, density, yield strength, Young’s modulus, etc.)

- Material selection is a lot more in depth with Ergo as compared to Frame, as you the specifications for each part may vary. While the entire frame needs to be one rigid piece, welded together and uniform, a single material will be used like 6361 aluminum or 4130 chromoly steel. However, with Ergo, you may need a light weight brake and accelerator pedals that are subject to a lighter load, but require a more rigid, easily weldable metal for the belly pan, that must hold high amounts of weight and therefore be exposed to high stress.

This is a stress-strain curve, one of the most fundamental parts of Solids. The graph has stress on the y-axis, strain on the x-axis

What you need to know is:

- The elastic region is where the material can have stress applied (elastic deformation) and the process is reversible (the material can go back to its original length)

- The elastic line on the graph is linear because the stiffness of material in this region is like a spring (most materials mimic the processes of a spring when it comes to deformation)

- This is also the same place where Young's Modulus comes into play.

- Young's Modulus is simply just a number that represents the "stiffness" of a material, representing the ratio of stress over strain. This is unique to each and every material.

- Most importantly, higher young's modulus means a more brittle material (less strain/yielding, can withstand more stress, but more prone to fracturing)

- The plastic region is where the material has stress applied (plastic deformation) and the stress overcomes the energy required to rupture bonds, which is an irreversible process

- Two important things: Yield Strength and Ultimate Strength

- Yield strength is the maximum stress a material can absorb before plastically deforming

- Ultimate strength is the maximum stress a material can absorb before fracturing (breaking)

- I’ll talk about this later on in the guide when we get to welding, but essentially, just know that we mainly design things around the yield/ultimate strength.

Pictured above, is a stress-strain graph showcasing some common materials. From left to right, we go from harder, higher "strength" materials, that lightly yield, to softer materials, lower "strength" materials, that yield more.

- Strength in this case just means a materials ability to take resist breaking when a stress is applied. A stronger material can take more stress before permanently breaking.

Another key point of materials that is more in play with Ergo as opposed to Frame is Resiliency as opposed to purely using Toughness.

- Resiliency is the ability of a material to absorb energy again and again without having some sort of permanent deformation. Think of a material like rubber, that has a fairly low work of fracture (meaning it can be easily fractured with a small-ish amount of energy) but if that level of energy is not reached, the rubber can yield again and again without deforming permanently.

- Toughness refers to sort of the same thing, but instead of focusing on permanent deformation (which can occur before and without any sort of fracture), Toughness focuses on the ability of a material to absorb energy without fracturing. This is more so a higher number with heavier metals, where a resiliency is better in softer materials that can easily rebound.

- In reference to Ergo, like previously mention, different parts require different materials for their intended situations. Specifically, sometimes you will need a material with the ability to not yield much and be able to take lots of energy and stress before yielding (like a brake pedal, as you'd never want your brake pedal to take the force of your foot by bending instead of activating your brakes). On the same hand, sometimes you'll want a softer material that can take a load, yield, but still not fracture and will go back to its original position afterward (think of anything with rubber or foam, like pieces of a seat or steering wheel)

Lastly, the Factor of Safety, at least in our case is measured with the yield strength of the material, as well as the max von Mises equivalent stress from the given simulation/reaction (the equation is Max eq stress/yield strength)

- This indicates when a part can fail

- FOS of 1 means the current simulation/reaction will begin to fail at 1 times the max equivalent stress, 2 means the structure begins to fail at 2 times the max equivalent stress, etc.

- FOS of 1 is the absolute bare minimum a structure should have before it is deemed manufacturable, but some parts of the frame must have a 1.1 minimum, due to high safety goals/concerns (although you should always shoot for something >1.6 FOS)

Solids

Start Here → Solids Lecture.pdf

There are 4 main types of stresses each tube will encounter. Those include:

- Normal Stress: Stress that acts perpendicular to the cross-section of interest (compression, tension, or rather axial force)]

- Shear Stress: Stress that acts tangential (parallel) to the cross-section of interest (like a cutting force)

- A common application of this is bolt shearing. This is where pre-tensioning, torqueing, and bolt calculations come in to play (tbd, I am learning about these currently)

- Torsional Stress: A shear stress that is caused by a moment about the longitudinal axis of the tube (think of a twisting force)

- Bending Stress: (THIS IS THE BAD ONE): Stress caused by a moment that has tension and compressive stress at each end (think of the cantilever beam problem below

- Also, bending stress is related to moment of inertia

- Simple Bending or Pure Bending A beam or a part of it is said to be in a state of pure bending when it bends under the action of uniform/constant bending moment, without any shear force. Alternatively, a portion of a beam is said to be in a state of simple bending or pure bending when the shear force over that portion is zero. In that case, there is no chance of shear stress in the beam. However, the stress that will propagate in the beam as a result will be known as normal stress. Non-uniform bending occurs when shear forces are introduced.

- Above is the formula for bending stress on this cantilever beam. Here, we have bending stress on the left side, with the calculated bending moment times the vertical distance from the neutral axis, all over the moment of inertia from the neutral axis

- What you really need to take from this is not necessarily all the algebra behind bending stress, but rather the things that affect the value itself, which in this case is bending moment, moment of inertia, and vertical distance.

Fluids/Thermodynamics

Specific to Ergonomics, you'll also utilize some Fluid Mechanics and Thermodynamics knowledge as it pertains to the braking system.

At its core, a braking system (or at least what Ergo deals with) is an assembly of brake lines, the brake pedal/E-brake, proportioning valve, and braking fluid, that converts the force of your foot on the pedal, into mechanical energy via a piston cylinder and fluid (this is the Thermodynamics aspect), and thereby into braking force on the brake rotors and by extension the wheels of the car.

A big point as it pertains to the braking system is the difference of compressible vs. non-compressible substances/fluids. In the braking system, we are working with brake fluid, which like water, is an incompressible fluid, meaning that when a pressure is applied, the fluid will move and transfer that pressure as opposed to taking it and becoming compressed

- However, when setting up a braking system, it's important to bleed your brakes, which just means purging the system of air bubbles. When you install brakes and therefore brake fluid, bubbles are present in the lines before bleeding. Because air IS compressible as opposed to your brake fluid, the air will compress and take energy and pressure away from the brake fluid as it's trying to move and activate your brakes. This is what causes a brake to become squishy and unresponsive, as when air bubbles are present you are basically just compressing and decompressing the air with minimal brake fluid movement.

- On the same type of note, using Thermodynamics, we know that when this pressure is applied, some of that energy flowing through the fluid will transfer to heat energy, which lead to brake fluid boiling. This is more so a concern of the driver (as excessive/improper braking is the cause of brake boiling), but this also plays into brake fluid selection. At its core, just like any water, is it is boiled, vapor is released, which contains air bubbles. As previously mentioned, if your brake fluid is boiling, and therefore, you create air bubbles, well I think you know where I am going with this...

More on the fluids side, there's some key principles that are helpful in setting up an optimized braking system

Firstly, Bernoulli's Principle refers to how fluid pressure and velocity are affected by the diameter of the tubing/line of a fluid (in our case the brake line)

- Simply put, if we assume the flow rate is the same across the entire tube/line, when the tube has a larger cross-sectional area/diameter, there's more volume in the tube, meaning the fluid travels slower and with higher pressure to achieve the same flow rate

- On the opposite side of the spectrum, when the tube or line has a smaller cross-sectional area/diameter, there's less volume, meaning the fluid must work harder and travel with more velocity to achieve the same flow rate, albeit with less pressure

- This is applicable when thinking about the sizing of your lines, especially as your braking ability is determined by the ability to move pressure from the brake pedal, through the fluid and to the actual brakes

Additionally, we have the different types of flow, laminar and turbulent flow, at play as well.

- Laminar Flow refers to a flow with little turbulence, creating a smooth, consistent stream

- Turbulent Flow is the opposite, referring to a more chaotic, inconsistent flow, that occurs due to turbulence

- Turbulence is just a term for irregular motion, like swirling and unpredictable changes in motion

- Point here being, you want to achieve laminar or close to laminar flow when possible as it's predictable and consistent. You want predictable and consistent braking ability right?

Lastly, piggybacking off of the types of flow, consider the pathing of your tubing. Consistent and smooth fluid streams are naturally better suited to straight, consistent paths, but inevitably you might need to change the directions and pathing of your lines.

- When creating direction changes in these lines consider the resultant drag caused by the abrupt change in the fluid's path as well as the turbulence it can create, which further affects the pressure and velocity values of the flowing fluid

- The red pockets on the corners symbolize points of flow separation, which just means that the smooth stream is broken up into sections, causing turbulent flow and pressure losses.

- All in all this just means that you should for as straight and consistent as a path as possible, and if you have to, utilize more gradual, smoother turns, as more abrupt and constant turning hurts fluid flow, leads to excess drag, as well as lots of pressure drops and turbulence

Topology Optimization

Useful Tidbits

Ergo Idea dump  :

:

- Wet layup carbon fiber molded seat, starts from foam CNCed mold that is then overlayed with carbon fiber, resin, etc.

- Composite, fully 3d printed steering wheel???? ( with 3d printed grips )

- Top-opped pedal box with lightweight materials

Related articles